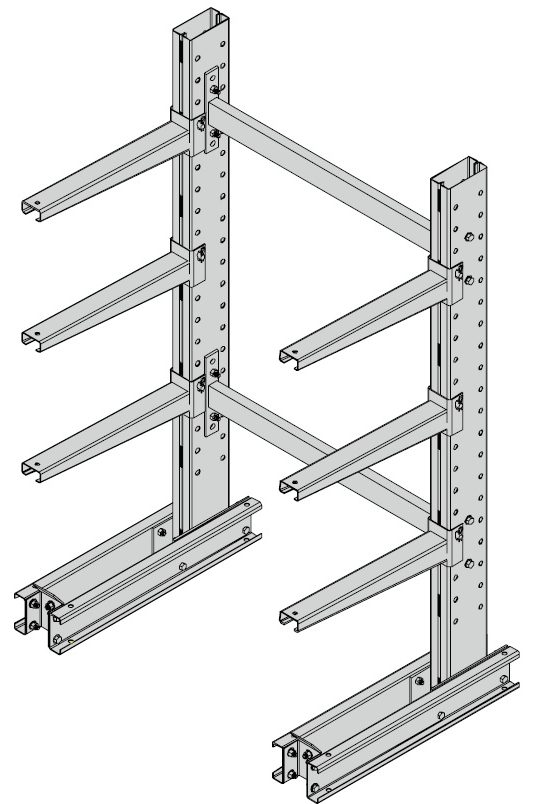

Questions to Consider When Purchasing a Cantilever Racking System

Are you preparing to purchase a new cantilever racking system for your warehouse? The main issues you need to consider when designing that system are the required arms, braces and uprights, as well as what you’ll be storing and how much storage space you need.

Here are a few key questions to consider when you decide you’d like to design and/or purchase a new cantilever racking system.

What are you storing?

This is the first question you need to consider when designing or purchasing any type of storage system. The materials or items you plan to store will have a significant impact on your storage and shelving needs.

Consider, for example, how long the items are that you are storing, how deep they are, how heavy they are and how many of the items you’ll have. Longer, heavier items will require different types and numbers of arm levels and columns than smaller, lighter items.

The answer to this question will inform everything else about the design of your cantilever racking system.

How many arm levels do you need?

Based on what you’re storing you can determine the spacing of the arms needed in the racking system, which will in turn tell you exactly how many arm levels you need. The load must be supported by a sufficient number of arms to prevent it from deflecting, which could cause damage to both the arms and the load itself.

The way you spread out the load depends on how many arms you’ll use. When using just two arms for a load, you will have half of the load length in between each arm, and a quarter of the length sticking out over each end. With three arms, you’d have a third of the length of the load between each arm, and a sixth of the length of the load sticking off each end. With four arms, you’d have a quarter of the length between each arm, and an eighth of the length sticking off each end. You get the idea.

The length of the arms is also important here. The depth of the load should never exceed the length/depth of the arm. This means if you have a 48” wide plywood bundle, the arms need to be at least 48” long.

How many columns do you need?

Similar to arm levels, the number of columns you need depends primarily on your needed load capacity. You also must consider the space you have in your warehouse for shelving. Consider the height of the ceiling, the reach you have with your forklift, sprinkler systems you have in place and their space needs and anything else that could factor into your shelving, such as building codes.

In general, it is better to have too many columns than not enough, as this will increase your load capacity.

For more specific information about how you can design your cantilever racking system and the factors that will determine upright and arm numbers, contact the experts at Industrial Shelving USA today.

More...

Categorised in: Cantilever Racking