What’s the Right Pallet Rack Layout for Your Warehouse?

No matter what your company does, do not underestimate the value of a well-organized warehouse. The secret to making a profit is efficiency. The right pallet rack layout can make all the difference in how your business performs. As a local source for pallet racking solutions, we know a thing or two about planning the right pallet rack layout. Want a few tips from our experts at Industrial Shelving USA? Read on to learn more!

Measuring

We’ve all heard the old adage, “measure twice, cut once.” Our experts say this is a good rule to follow when planning your pallet rack layout. You want to get an accurate idea of the floor space you’ll be using for your pallet racks. You should measure not only how much space you have for the actual racks, but also the space you need for people to walk and maneuver forklifts and other machinery. You’ll also want to consider things like support beams, curbs and pipes. You don’t want any space to go to waste, but you also want to make sure that you don’t crowd your warehouse so that your employees can’t move around safely and efficiently.

Safety

When planning your layout, you don’t want to do anything that might become a hazard or a safety issue. Be sure to be mindful of exits, outlets, vents and other emergency- or safety-related facets of your building. You don’t want your pallets affecting or blocking anything in your warehouse space. You should also review any safety regulations and policies to ensure that your layout is aligned with these guidelines.

Vendor

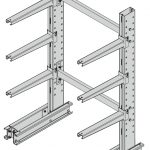

Once you’ve determined where your racks should go, it’s time to bring in a professional to help you choose the right pallet racking solutions to meet your needs. For example, wire decking is more flexible and offers easy access. It’s perfect for lighter items that need to be moved frequently. For heavier items that will more or less stay put, you may need steel racks. An expert in warehouse storage will be able to help you choose the best pallet racking solution for your warehouse.

Assembly

If you are assembling the racks yourself, the planning doesn’t end when the racks arrive. You’ll want to carefully mark where each rack will go prior to assembly, to help avoid misusing space or accidentally assembling a shelf in the wrong position or wrong spot.

Maintenance

Finally, ensuring warehouse safety and efficiency doesn’t end when the shelves are up. It’s important to make sure that your pallet racks are well maintained and assess for any safety issues. You will also want to reassess how your layout is working for you as your business’ operations grow and change.

If you want to ensure that your business operations are efficient, safe, and profitable, apply these expert tips to your pallet rack layout. If you are looking for a vendor for top-quality pallet racking, be sure to call Industrial Shelving USA, your nationwide warehouse storage experts. We look forward to working with you soon!

More...

Categorised in: Pallet Racks