New Pallet Rack and Installation crews in all states. Please request a free quote for your Pallet Rack Installation.

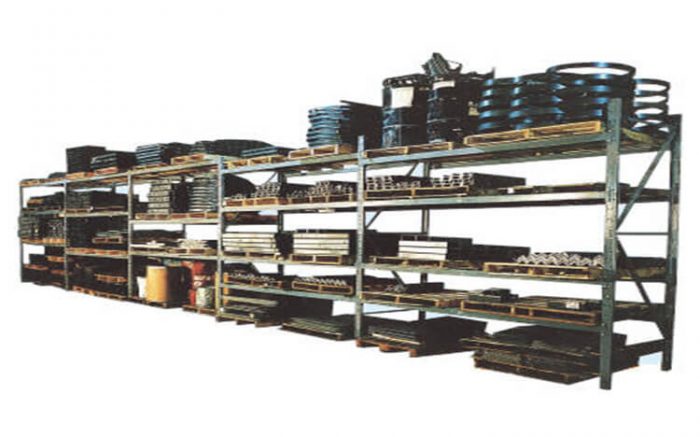

Pallet Rack Shelving

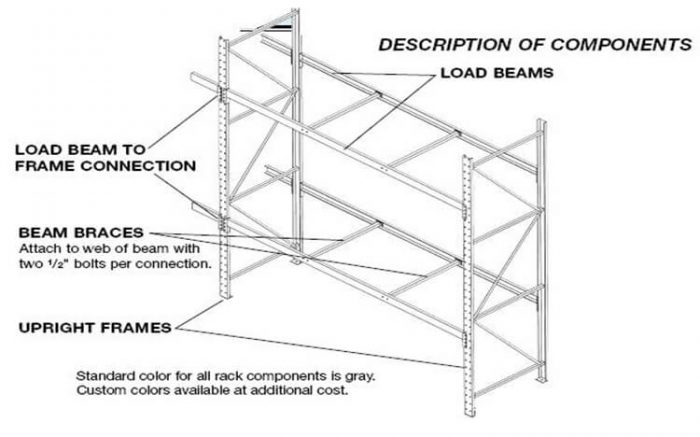

Upright Frames

Load Beams

Structural Rack Accessories

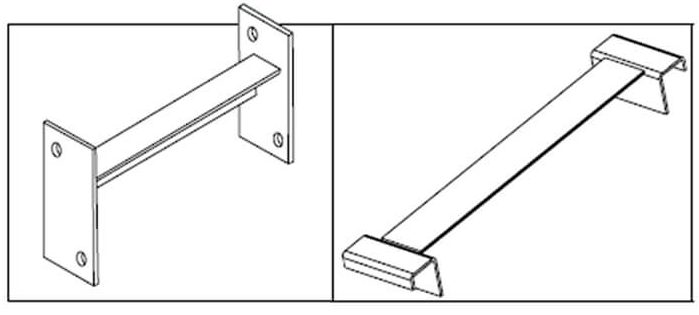

Permit linking a row of racks to either the wall or back to back row of racks. Maintain spacing while providing additional stability to the system.

Prevent undersized loads from falling through the beams, support week pallets or serve as deck support. Both drop in and bolted models are available

Provide extra protection from forklift abuse in the lower frame areas.

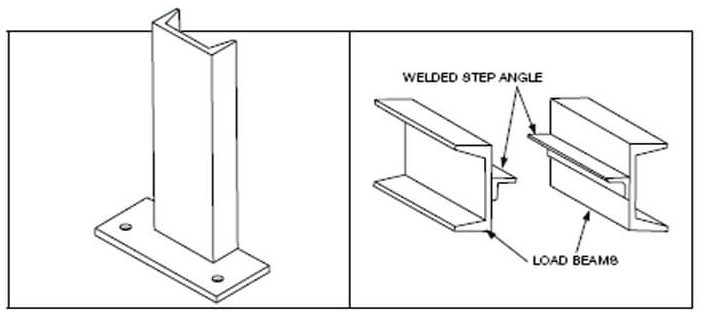

Permit a custom deck to be placed in the pallet rack system for added veracity. Steps angle is factory welded to the inside of the load beam at custom heights to meet individual requirements.

Drive-in-drive-thru structural pallet rack the most efficient method to store large quantities of similar pallet loads

MECO OMAHA Drive-in Rack installation.

Custom-designed for high density storage and efficient handling.

Satisfy your high density bulk storage requirements with a drivein/ drive-thru system from MECO OMAHA. Drive-in systems allow forklift entry from one direction only—ideal for a first in/last out inventory system. Drive-thru systems allow the forklift to enter the rack from either the front or rear and move pallets completely through the structure. This system works best in a first in/first out system. Both drive-in and drive-thru racks reduce the need for conventional aisle space and maximize warehouse utilization.

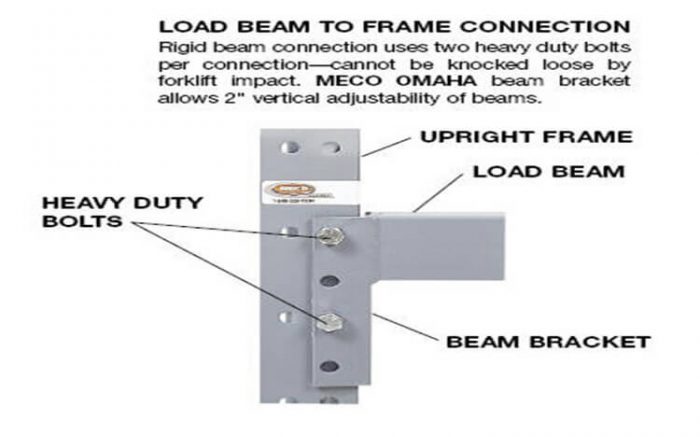

MECO OMAHA drive-in/drive-thru racks are custom designed to fit your specific storage application. Upright frames, pallet support beams and cross ties are fabricated from structural channel providing optimum strength and durability. Upright frames are punched on 4″ centers, special bracket allows 2″ vertical adjustability of rail supports. Structural angle load rails are mounted to rail supports by a special bracket eliminating screws or bolts on the rail surface— pallets cannot be damaged by obstructions. All connections are accomplished with plated, heavy duty bolts and nuts—cannot be dislodged by forklift impact; installation is fast and easy with no special tools required. Contact your MECO OMAHA representative for custom-designed drive-in or drive-thru rack systems. MECO OMAHA sells drive-in/drive-thru structural pallet rack to approved dealers only.